Electrostatic Precipitator Training Manual

- United States Environmental Protection Agency. EPA-600/R-04-072 July 2004 Electrostatic Precipitator (ESP) Training Manual EPA-600/R-04/072 July 2004.

- Electrostatic Precipitator (ESP) Training Manual - Scholar's Choice Edition [U.S. Environmental Protection Agency] on Amazon.com. *FREE* shipping on.

Training Services B&W provides a variety of technical training seminars designed for busy plant personnel. We continually strive to provide seminars and training programs to meet the needs of our customers. Seminar participants will hear from recognized experts in the subject area, and will receive written material to reinforce the lessons learned in presentations. To meet plant-specific needs, our courses are frequently modified and new courses are developed. Complete curricula to fulfill job progression and qualification requirements for many disciplines are available.

We can also tailor our standard courses for special requirements. Customer feedback has consistently been positive.

Document Display (PURL) NSCEP. Electrostatic Precipitator Knowledge Base. The Neundorfer Knowledge. Base is an industry- leading information resource about.

We are committed to providing the most efficient, cost effective training by utilizing and exploring today’s technologies in all areas of training. Benefits of Our Training Programs Training is an investment with many short- and long-term benefits. Two important benefits that directly affect your bottom line are reducing plant operating costs and downtime. Other benefits have a more indirect effect. Training builds confidence and develops skills of plant personnel, improving both morale and efficiency. By improving plant safety through quality training, an organization can reduce its workers’ compensation claims and accident-related absenteeism.

Training personnel to operate and maintain equipment properly, safely and efficiently can help companies ensure reliable plant performance. Seminar Description: This seminar educates participants on the theory and operation of electrostatic precipitators (ESP). Seminar participants will explore the factors that affect ESP performance, normal maintenance techniques and procedures. Also included are techniques to optimize the operation of B&W precipitator control technologies (such as the SQ-300 ®i controller, PRC-100 ® rapper controller and Precipitator Manager TM software), and current trends in energization of precipitators. Participants will learn methods to improve the performance of existing precipitators to meet regulatory compliance goals. Schedule: Reception: Monday, 5:00 PM to 8:00 PM Seminar: Tuesday and Wednesday, 8:00 AM to 5:00 PM Thursday, 8:00 AM to Noon. Seminar Description: This seminar provides knowledge and skills for proper operation and maintenance of large boilers used for electric power production.

The seminar is designed specifically for utilities using pulverized coal as a primary fuel source. Covered in the course are boiler and boiler component design, safety, inspection, maintenance, firing systems and pulverizers, and methods for overall increased boiler availability and reliability. Schedule: Reception: Monday, 5:00 PM to 8:00 PM Seminar: Tuesday and Wednesday, 8:00 AM to 5:00 PM Thursday, 8:00 AM to Noon.

Precipitator Training

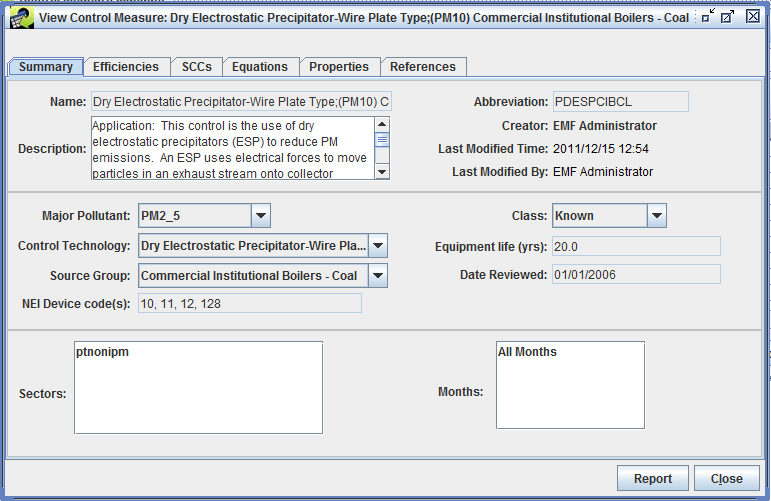

Description: The manual focuses on the operation and maintenance (O/M) of typical electrostatic precipitators (ESPs). It summarizes available information on theory and design in sufficient detail to provide a basic background O/M portions of the manual. Although O/M-related air pollution problems cannot be completely eliminated, they can be minimized by the conscientious application of a well planned O/M program. The causes of such problems often very widely, and their effects on deteriorating performance may be direct, indirect, or synergistic. Process, particle, mechanical, environmental, and gas-flow-dynamics factors dictate that O/M programs and troubleshooting be approached from a total system or process/plantwide viewpoint. The variable nature of these factors also requires that O/M programs be individualized and specifically tailored to the needs of the process and installation served. Effective O/M also affects equipment reliability, on-line availability, continuing regulatory compliance, and regulatory agency/source relations.